Digital Dentures – Pembroke Pines, FL

Creating Dentures in The Digital Age

Traditionally, the process of creating fully-customized dentures involves fabricating several different molds and re-checking the fit multiple times. When all is said and done, this method can take a couple of weeks to a few months. At Friedland Family Dentistry, you won’t have to wait nearly as long to receive your new teeth! Digital dentures enable us to provide patients with faster turnaround times as well as a more precise, comfortable fit. See how our modern technology can improve your treatment experience.

What Are Digital Dentures?

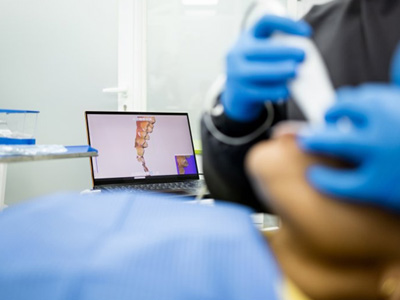

Digital dentures are essentially a virtual model of what your physical dentures should look like. Using dental impressions and advanced Cone Beam CT Scanner imaging, we’ll record 360-degree information about the size and shape of your mouth. This information will help us (and our partners at the dental lab) determine the proper measurements for your dentures. With our computer-aided design (CAD) software, making small tweaks to the model is simple, and can be done down to the tiniest inch.

How Are Digital Dentures Made?

First, we’ll send your digital denture data to skilled dental lab technicians. They’ll fabricate a physical version of your dentures that you’ll be able to try on in our office. If necessary, we’ll record adjustments you’d like to be made and feed them into the virtual model. The lab technicians will receive this updated information more or less instantly and will complete the process by printing and assembling the “final draft” of your dentures!

Benefits of Digital Dentures

Being able to streamline the denture creation process with digital design benefits you in a number of ways. For example:

- Your dentures will fit more comfortably and accurately

- The aesthetics of your dentures will be pristine

- You’ll have greater flexibility

- There will be fewer office appointments

- If you need a replacement, new dentures can be made quickly